🏭 Ganim Manufacturing User Manual#

Ganim's Manufacturing module allows you to efficiently manage production workflows, from planning and assembling raw materials to tracking manufacturing orders and analyzing performance. This guide provides a step-by-step approach to help you navigate the system with ease.

1. Accessing the Manufacturing Module#

- Log into your Ganim account.

- From the left sidebar, click on Manufacturing to access the Manufacturing module.

2. Navigating the Manufacturing Dashboard#

The top menus include:

-

Operations: Manage manufacturing orders and work orders.

-

Master Data: Manage bills of materials and routings.

-

Planning: View schedules and production plans.

-

Reporting: Analyze manufacturing performance.

3. Creating a Manufacturing Order (MO)#

-

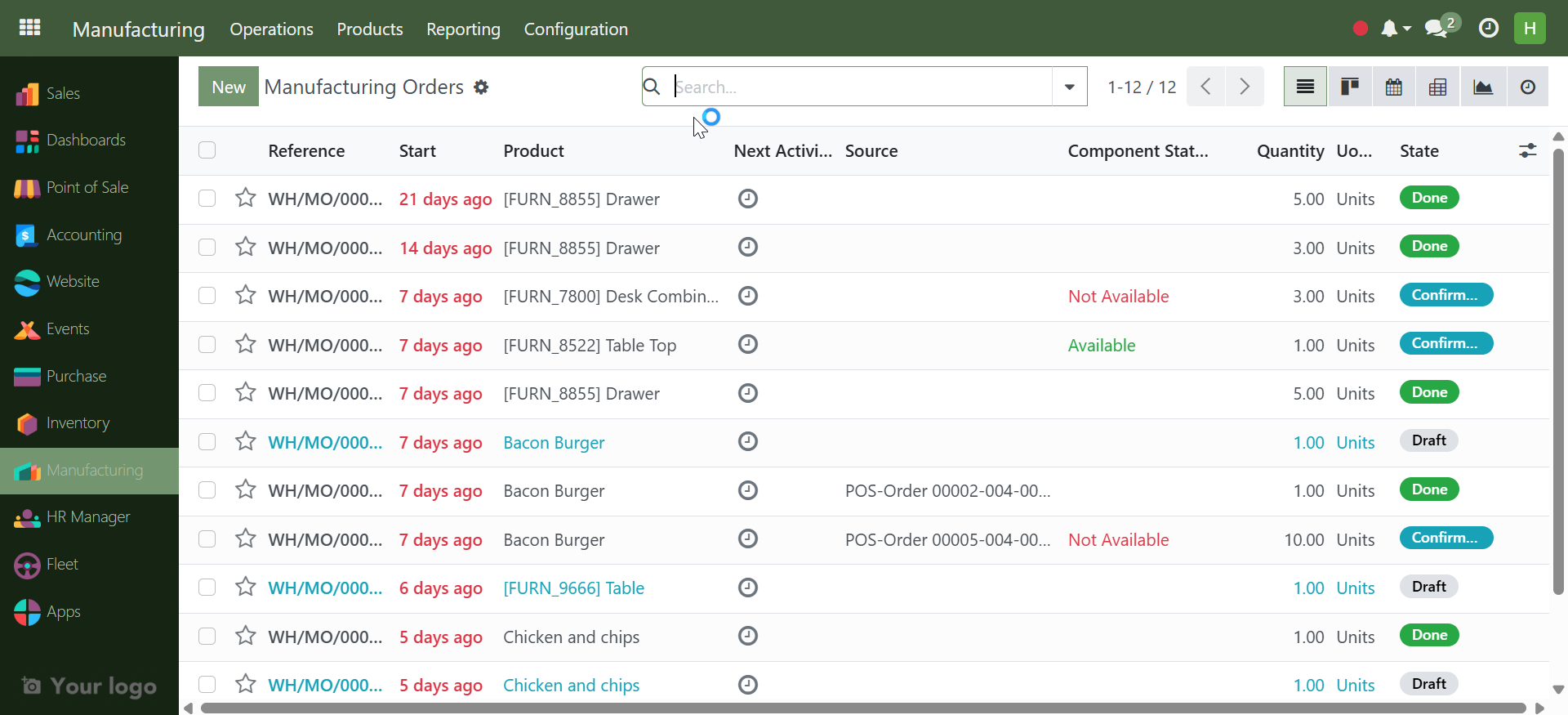

Click on Operations → Manufacturing Orders.

-

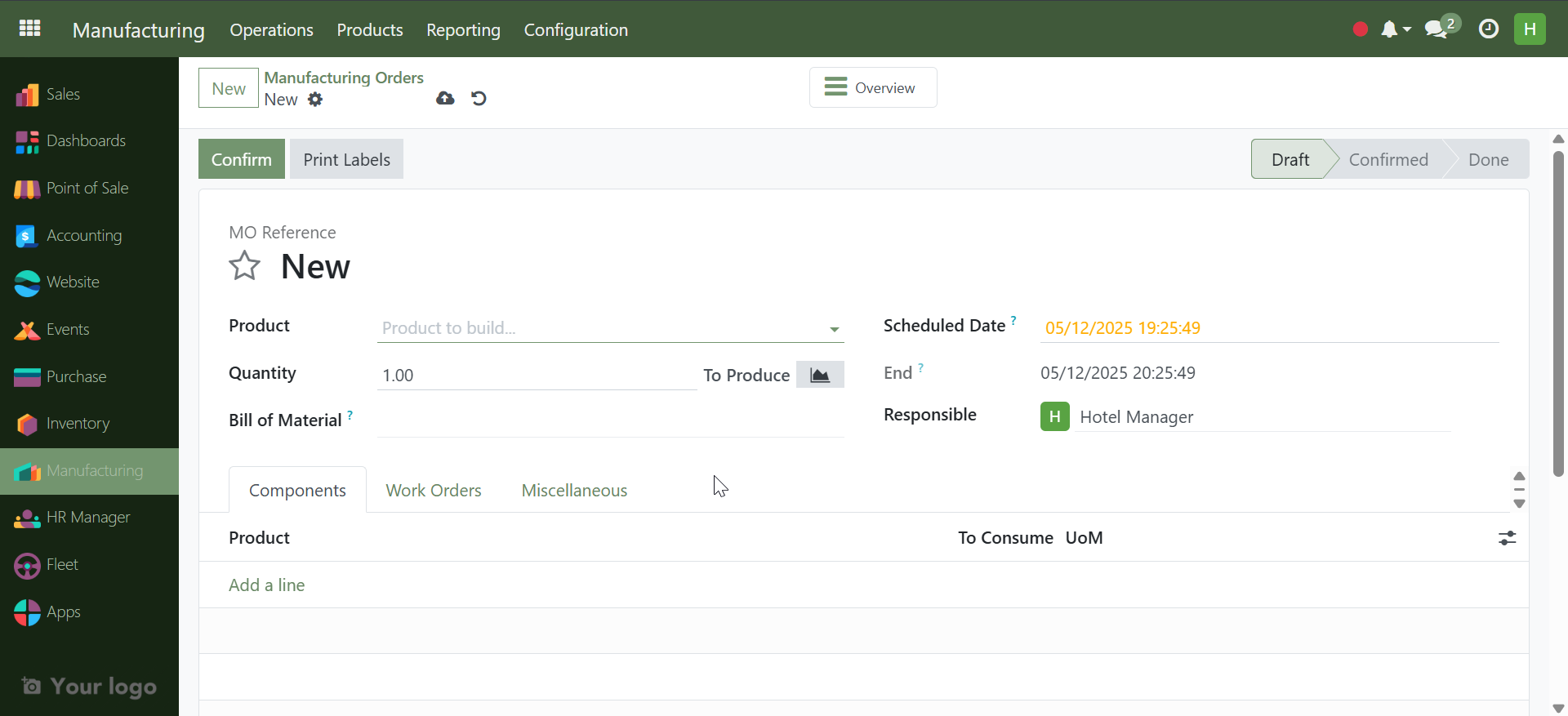

Click New.

-

Select the Product you want to manufacture.

-

Enter the Quantity to Produce.

-

Ensure the correct Bill of Materials (BoM) is selected.

-

Choose a scheduled Deadline (optional).

-

Click Confirm to validate the order.

-

Click Mark as Done when production is complete.

4. Setting Up Bill of Materials (BoM)#

-

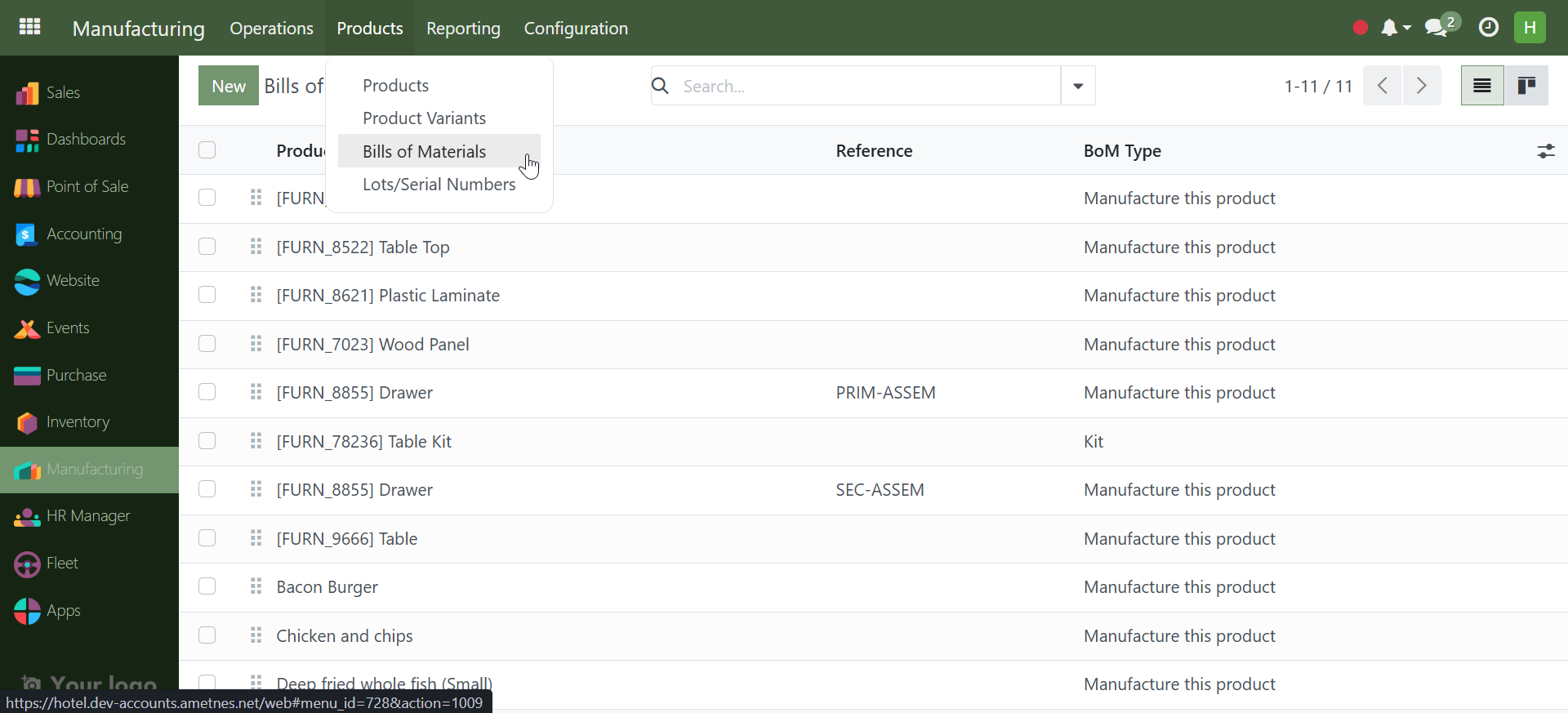

Go to Products → Bill of Materials.

-

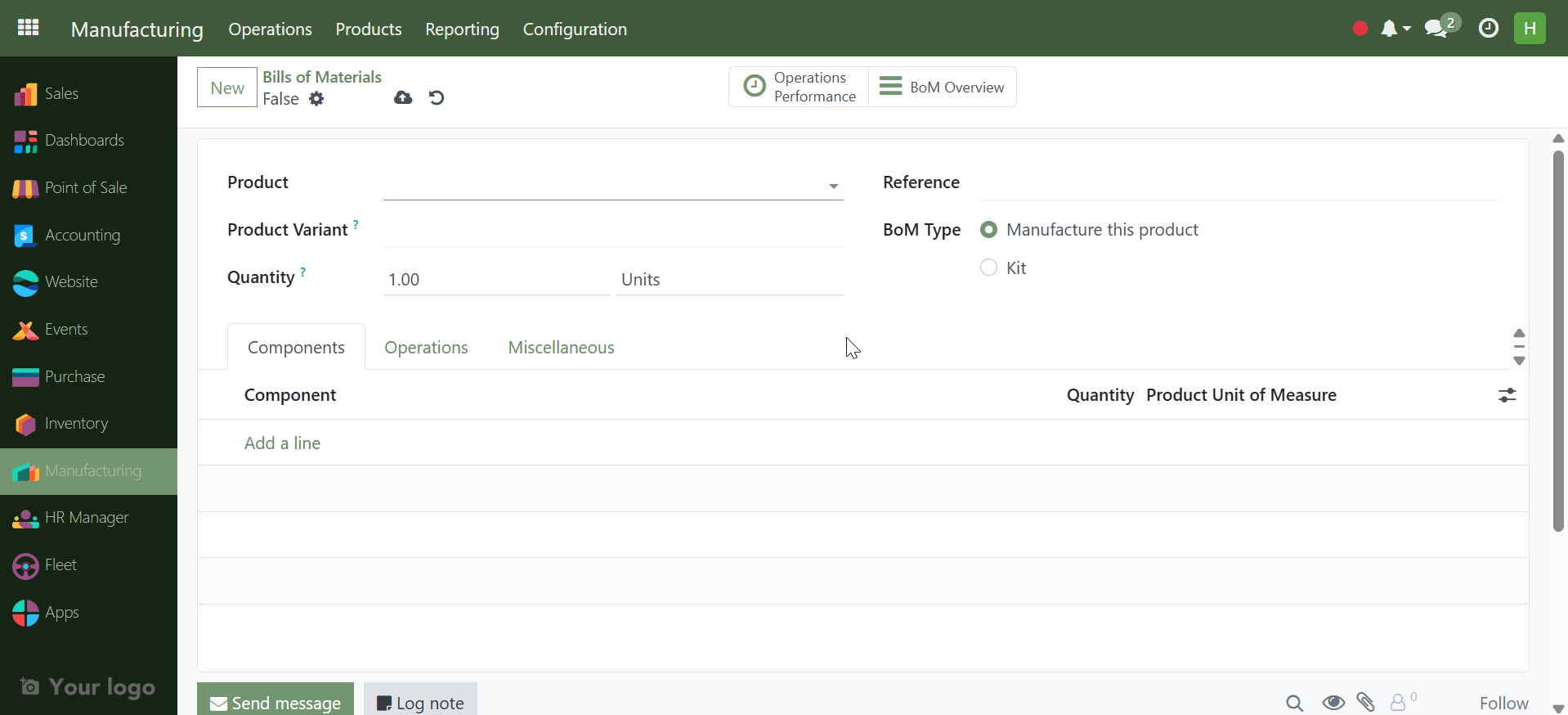

Click New.

-

Enter the Product you’re producing.

-

Under Components, add the items required (raw materials).

-

Optionally assign a Routing if specific work centers or steps are needed.

-

Save the BoM.

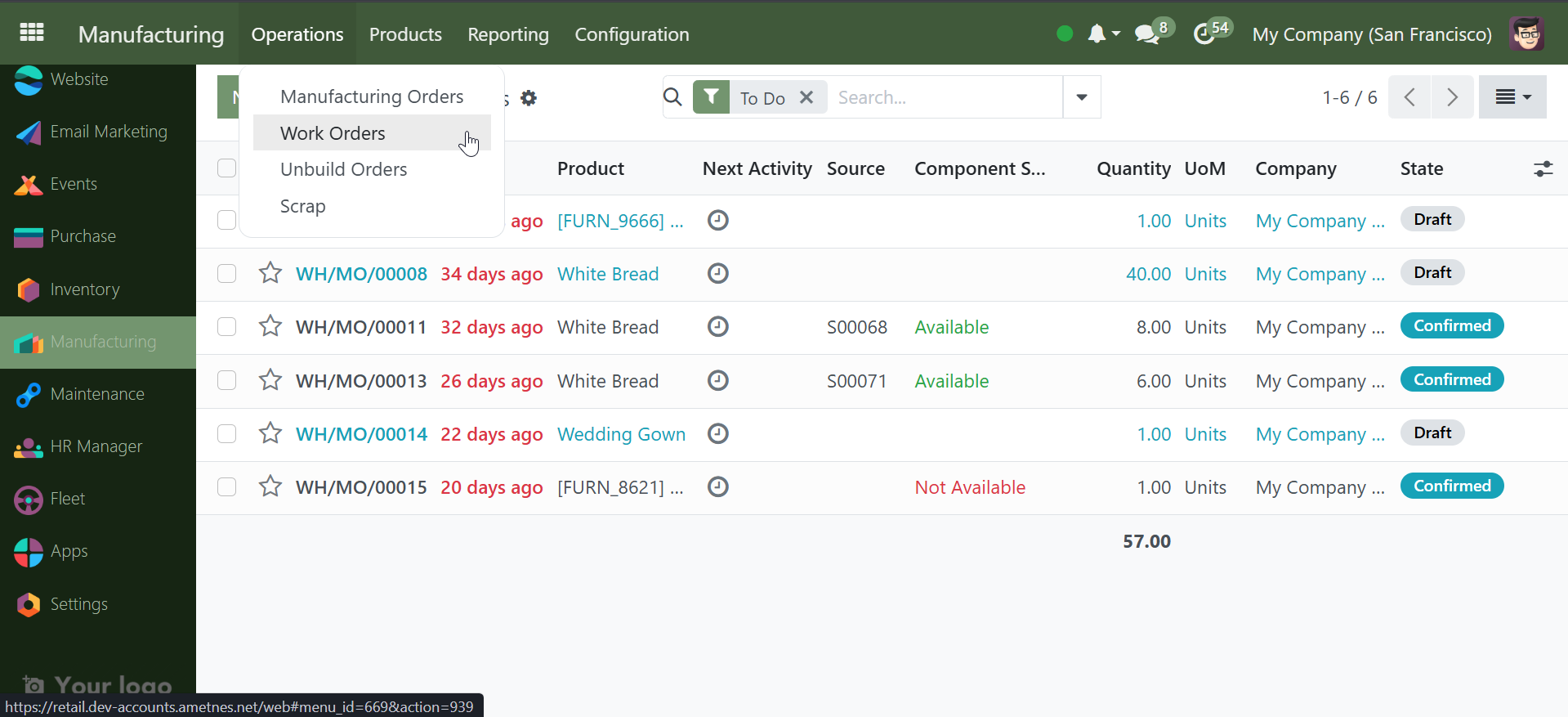

5. Viewing Work Orders#

-

If the product uses a routing, work orders will be automatically generated.

-

Go to Operations → Work Orders.

-

Each work order shows the task, work center, and time taken.

-

Click into a work order to Add components, Add time tracking, or Mark as Done.

6. Checking Product Availability for MO#

-

Inside a Manufacturing Order, click Check Availability to verify if all materials are in stock.

-

If not available, Ganim will show what’s missing.

-

You can manually replenish from Inventory or create a Purchase Order.

7. Additional Configuration#

Under Configuration:

-

Work Centers: Define machines or stations used in routing.

-

Production Locations: Customize where goods are produced and stored.

✅ You're Ready!#

You now know how to:

- Access and navigate Ganim Manufacturing

- Create Manufacturing Orders and BoMs

- Track work orders and material availability

- Analyze production efficiency

You're ready to manage production operations in Ganim with confidence!